Why Waste Material When We Can Capture and Reuse It?

Material shortages, staffing and supply chain issues, and constantly increasing prices for what material is available make every ounce more valuable, and every ounce wasted more costly. Allowing material to be discarded when we have the ability to capture, recover, and reuse it never made much sense but now that we can provide a net savings by recycling in nearly every case, there isn’t even financial justification for landfilling material as waste.

Conveying Systems Automate Recycling

We’ve been designing and manufacturing pneumatic vacuum conveying systems that automatically capture and recycle excess, off-spec, and waste material for many decades, for hundreds of different materials, all over the world. Of the many different installations, the food, pharmaceutical, and 3D printing examples that follow show how recycling saves on material and disposal costs, streamlines the overall process, and even improves sanitation and worker safety:

Snack Food Conveying and Recycling

A snack food manufacturer was dispensing salt as a curtain onto pretzels as they moved down a belt conveyor towards the oven. Most of the salt, of course, lands on the conveyor, not on the pretzels. Our system captures this excess salt in a hopper and automatically transfers it inside enclosed piping back to the dispenser for reuse. This controls dust and prevents contamination, and there’s no worker involvement required.

Recycling Pharmaceutical Active Ingredients

For a pharmaceutical company manufacturing tablets with a roller compactor, our conveying system automatically feeds the mixed powders into the compactor, then collects any fines, small granules, and excess material, and transfers it for sieving, granulation, and return back to the compaction process. The APIs are too precious to let them go as waste. The process engineer was happy to recover the excipients, too.

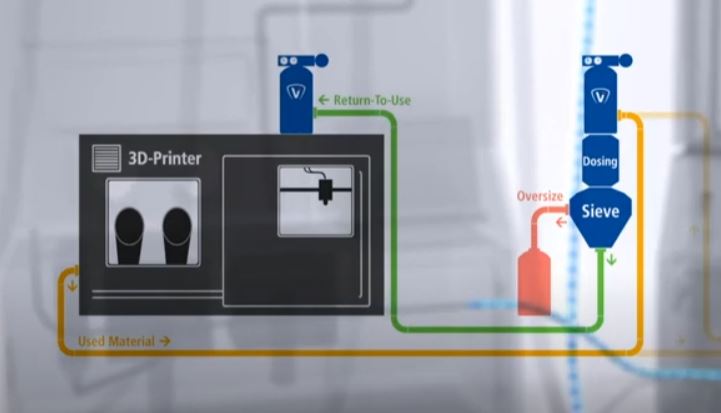

Conveying and Recycling Metal Powders

In additive manufacturing, the 3D printing process typically leaves a significant amount of metal material in the printer. Not only are these materials expensive and challenging to source, making reuse essential, but many are also hazardous and need to be contained. Manual collection of this excess material must be avoided. Our PowTReX metal powder recovery system automatically captures the excess or spent material, returns it to the proper particle size with ultrasonic screening, and transfers it to a hopper or bin for reuse. It’s an enclosed, contactless process that protects material purity and keeps workers safe at the same time.

Recovering and reusing what used to be considered waste material has become so vital that many of the leading manufacturers of 3D printers, filling and packaging machines, and other equipment specify our conveying systems as part of their original equipment to offer recycling as a standard feature.

Learn more about conveying your materials here.