Volkmann designs and manufactures bulk bag unloading stations, sack tipping stations, and other equipment for emptying big bags, drums, FIBCs and other containers. This line of powder process equipment delivers efficient, safe, and complete emptying with smooth, dust-free material transfer for feeding the powder or other bulk materials into a companion pneumatic vacuum conveyor system. Wide range of custom options available to accommodate nearly any bulk material handling application.

RNT Series

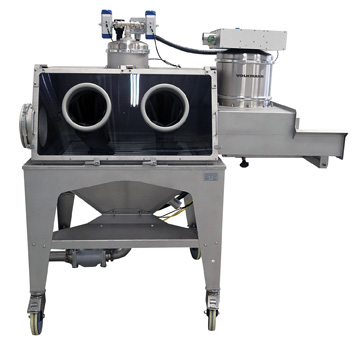

Volkmann RNT Series bag and sack dumping stations enable bagged powders and other dry, bulk materials to be neatly and safely loaded into a vacuum conveying process to reduce manual bag handling and prevent dust from escaping into the workplace.

Stainless steel, ATEX-certified, explosion-proof construction with wide range of custom options such as dust hood and filter, safety screen/grid, glovebox for high containment.

Available in 180, 80, and 40 liter sizes and in custom sizes.

BBU Series

Volkmann BBU series bulk bag / FIBC unloading stations feature stainless steel construction with heavy duty frames suitable for dust-free emptying of bags up to 1,400 kg.

Modular design is offered in custom configurations to fit nearly any space. Optional lump breaker, agitator, and bag massagers promote complete discharge of non-free flowing materials.

Containment Systems

Volkmann bag unloading stations can be customized to suit nearly any high containment requirements to safely load toxic materials into a process with maximum worker protection and dependable contamination prevention.

Try semi-automated operation to reduce worker involvement, WIP – CIP – SIP compatibility, empty bag compacting and removal device, and more.

.

© 2024 Volkmann, Inc. | All rights reserved | Privacy Policy