Pneumatic Vacuum Conveyors

Pneumatic Vacuum Conveyors

VOLKMANN Vacuum Conveyors automatically transfer dry powders, granules, pellets, tablets, and other bulk materials and small parts from storage in bags or silos to hoppers, mixers, containers, reactors, and other process and packaging line destinations.

Volkmann designs and manufactures these versatile vacuum conveying systems to gently transfer a wide range of bulk materials under vacuum in lean and dense phase. Enclosing the materials in hoses and pipes keeps the product safely contained for protection against contamination and keeps the production environment clean and free of dust. They are quick to install, easy to operate, and work day and night with very little maintenance.

Transfer nano-sized material and fine dust from 0.1 µm up to larger sized tablets, candy or bottle caps, often using the same vacuum conveying system. Volkmann conveyors are proven effective for transferring highly abrasive powders, mixtures, blends, and even materials with very light bulk densities such as fly ash and fumed silica with only 0.05 kg/l . Yet Volkmann vacuum systems also work just as well with heavier materials such as 3D printing metal powders for additive manufacturing with a bulk density of 10 kg/l.

Plus, Volkmann pneumatic conveyors disassemble easily without tools for fast cleaning and hassle-free product changeovers.

Learn How Pneumatic Vacuum Conveyors Work

Volkmann pneumatic vacuum conveyors gently transport fine food powders, chemicals, pigments, finished pharmaceutical tablets, and many other bulk materials by suction in either lean or dilute phase, or dense phase plug flow conditions as needed without material separation, damage, or abrasion.

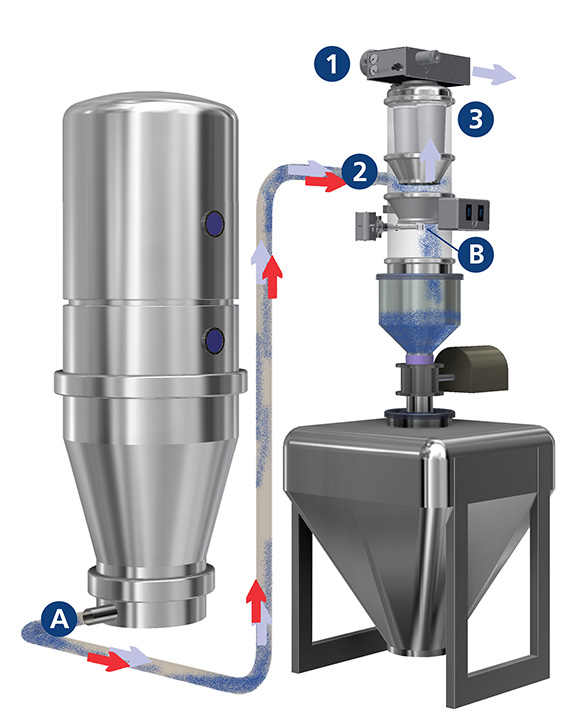

See step by step how to convey bulk materials using a pneumatic vacuum conveyor:

(1) Volkmann vacuum pump generates vacuum air flow using proprietary technology.

Suction air flows from product feeding point (A) to vacuum conveyor suction inlet (2), drawing material through the piping from storage.

Conveyor filter module (3) separates any dust and product from the pneumatic conveying air.

Transported product collects in the separator below the filter module.

Vacuum pump switches off automatically and product is discharged through a pneumatically operated flap valve (B) into the destination equipment or vessel.

Flap valve closes and the cycle repeats.

Volkmann Conveyors Are Explosion-Proof by Design

Volkmann pneumatic vacuum conveyors are explosion-proof by design, suitable for material transfer in hazardous environments, and ATEX-certified documenting the fact. Rely on Volkmann to safely convey ignitable powders and combustible dust even if flammable atmospheres and gases are present. Learn more about bulk material handling in explosive situations here.

A Volkmann Vacuum Conveyor offers the Food, Pharmaceutical and Chemical industries:

- user friendly systems with safe material transfer

- easy material aspiration and dust-free loading of machines

- gentle dense phase conveying, no segregation of material mixtures

- optimum hygiene conditions

- reliable filter systems in GMP quality

- simple installation and operating

- low energy consumption

- favorable investment- and operating costs

Pneumatic Vacuum Conveyors Meet Sanitary, Hazardous Requirements

Volkmann offers a choice of conveying systems engineered to suit nearly any regulated, non-regulated, hazardous, or sanitary process. These powder and bulk material transfer systems are delivered with quick lead times, and custom conveyors are offered for unique engineering challenges.

Versatile workhorse offers a compact, modular design that can be quickly installed off the shelf for transferring a variety of bulk materials and ingredients from fine, powdered sugar to roughly cut pieces of ham to loose mixtures like trail mix.

Hygienic conveyor developed specifically for pharmaceutical processing and other industries with especially strict requirements for cleanability and data integrity.

Proprietary vacuum conveying technology safely transfers materials under inert gas for discharge into critical process areas.

Designing Your Vacuum Conveying System – Use Tubing or Pipe?

Volkmann uses enclosed flexible hose or stainless steel tubing to protect the material in transfer from contamination due to exposure to the environment and to protect workers from exposure to the material for a safe, dust-free workplace.

The rigid, metal tubing offers a smooth interior that promotes flowability, even when transferring cohesive powders. For transferring corrosive materials and/or for sanitary processing, stainless steel needs to be specified. In fact, every Volkmann vacuum conveyor comes in the FDA-compliant stainless steel suitable for food, beverage, petfood, pharmaceutical, and other sanitary processes.

When using a vacuum conveyor to transfer bulk materials over – learn more

Test Your Material in Our Pneumatic Vacuum Conveyor

Volkmann USA offers material testing on full size, fully operating pneumatic vacuum conveyors in a dedicated test laboratory in Bristol, PA.