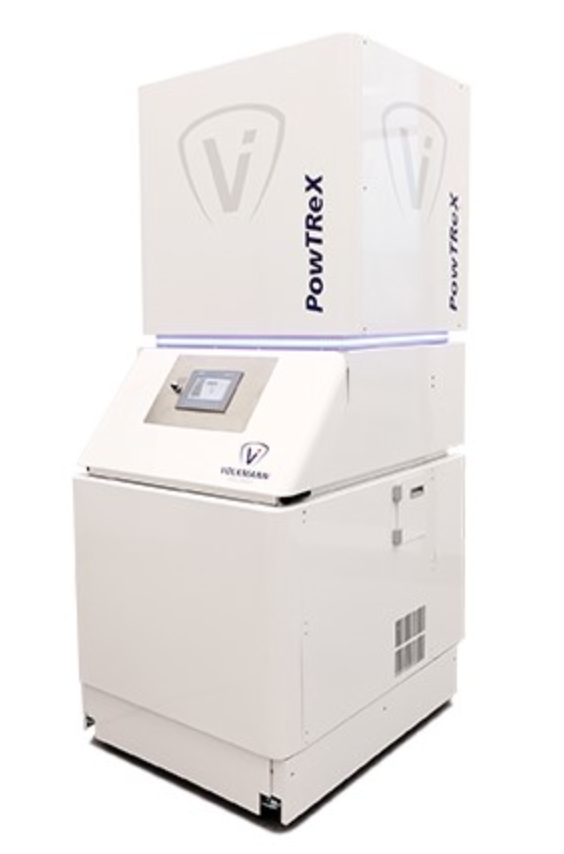

PowTReX series

PowTReX SERIES POWDER TRANSFER, RECOVERY, AND EXTRACTION SYSTEM

PowTReX: powder transfer, recovery and extraction system

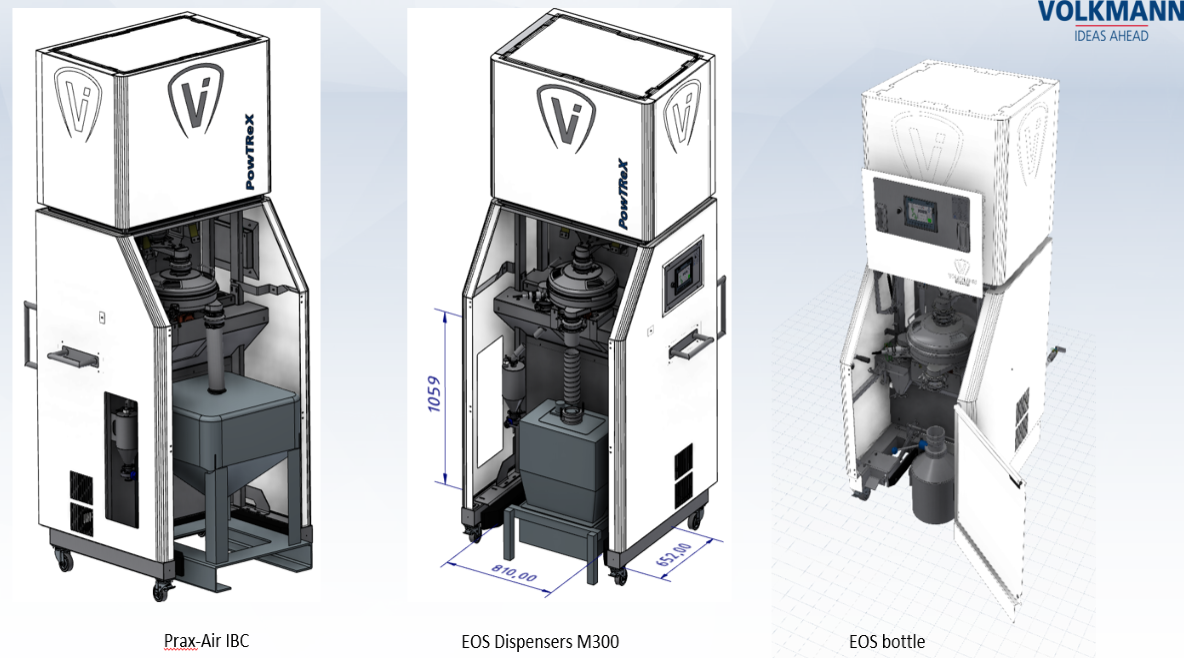

PowTReX system automatically transfers 3D printing powders from a container or supply hopper to the printer, extracts and sieves unused metal powder after a completed build job to remove oversize particles, and collects the sieved powder for return into the process. The integrated vacuum conveyor directs the powder transfer into a small internal buffer hopper to allow continuous, metered feed onto the vibrating screen for sieving. Fused bits and agglomerates from the laser powder bed fusion (LPBF) process are removed and the clean, recovered powder is collected in a discharge container, filled into bottles, or directly picked up and conveyed to downstream equipment.

VOLKMANN PowTReX integrated powder sieving solution

PowTReX / PowTReXi

PowTReX basic

PowTReX Advanced

Customized PowTReX

Advantages and Features:

- Closed and dust-free powder handling

- ATEX certified

- UL 508a controls

- Safety: Secondary Filter HEPA (H14)

- Ultrasonic screener for reliable powder recovery

- Multiple available screen mesh sizes

- Mobile system usable on multiple 3D printers

- Improved ergonomics: no powder-lifting for the operator

- Easy to dismantle and easy to clean for product changes

- Reduced processing time and required labor

PowTReX with open access doors showing vibrating screen and VOLKMANN 50 liter mobile discharge container