3D Printers Needed a Vacuum Dryer to Dry Metal Powders

How We Developed Our New Drying System for Additive Manufacturing

3D printing companies weren’t clamoring for a new vacuum dryer. But many of our additive manufacturing customers were realizing that the moisture content of the metal powder when it enters the build box plays a decisive role in whether the printed metal part meets targeted quality specifications. Adding to the challenge, many of the metal powders commonly used in 3D printing such as aluminum and titanium are hygroscopic – they absorb moisture from the ambient air.

3D printing powders contaminated with moisture often result in parts plagued with a variety of defects that render the metal parts as costly waste. It’s a critical obstacle hindering the widespread growth and adoption of additive manufacturing as a fast, cost-effective alternative to traditional metal fabrication and machining.

Many printers and 3D printer manufacturers experimented with ovens and other ways to dry their metallic powders but for an industry focused on improving speed and efficiency with automation, adding a separate step to the process is to be avoided. Applying heat to powders that melt also needs to be avoided.

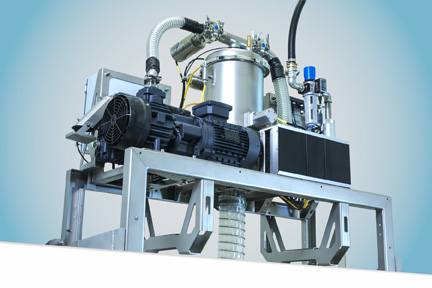

Our new vDryer vacuum dryer automatically restores metal powders to acceptable moisture levels. Instead of using external heat, we use a pump that creates a deep level of vacuum. This evacuates the moisture without heating, melting, or damaging the sensitive materials.

Further, this is automated technology installed inline atop the printer – no extra steps are needed for material conditioning. The dryer can also be installed downstream from the printer to prepare used material for screening, storage, and/or reuse. Of course, it’s vital to control the humidity and temperature of the facility but even in a controlled environment, keeping hygroscopic metal powders from absorbing airborne water is no easy feat. But now, keeping these powders at the precise moisture content required for 3D printing is easy and hands-free – with the vDryer.

Even better, the vDryer is offered integrated with our vLoader, which automatically loads the dried metal powders into the printer.

See a completely automated additive manufacturing process here.