Rotary Valves for Powder Allow Continuous Transfer

For Non-Stop Discharge of Bulk Solids, Try Volkmann Rotary Airlock Valves

Experienced engineers with expertise in dry bulk material processing know that we design and manufacture pneumatic vacuum conveyors to transfer powders and other bulk solids – safely, gently, and efficiently. But even veteran, long-tenured process engineers may not know that we also design and manufacture rotary valves for powder processing.

Why? Standard pneumatic vacuum conveying systems transfer powder intermittently in separate suction and discharge cycles. This is the best practice for many bulk material transfer applications. However, some applications require a continuous discharge of bulk solids to supply a reliable, non-stop flow of material to the mixer, hopper, or other vessel. In these automated conveying systems, a rotary valve allows the material to flow uninterrupted.

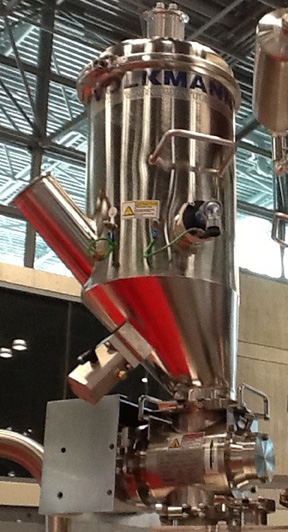

We tested the best rotary valves available at the time and realized if we wanted to feel confident in the performance, we needed to design our own. A rotary airlock valve needs to establish a leak-proof, air-tight seal between the vacuum receiver upstream and the hose or piping at the discharge. This creates the proper pressure differential that allows the material to flow freely around the rotor and out the discharge. A number of those we considered either had trouble maintaining the seal over time or would wear faster than we felt was acceptable. Our proprietary Volkmann design uses 100 percent stainless steel in product contact areas as standard – just like our conveyors – as part of our overall commitment to safety and hygiene.

In fact, these continuous vacuum conveying systems are running in food, nutrition, and pharmaceutical plants, often 24/7. The valve seals and connections fit seamlessly as a companion with our pneumatic vacuum conveyors and they are easy to take apart for quick cleaning. For hazardous situations with ignitable powders or combustible dust, our rotary valves are ATEX-certified as explosion-proof, just like our conveyors.

No matter the conditions or process requirements, we’ll figure out exactly the right conveying solution. Question about your process? Click here and our sales engineers will give you a call.